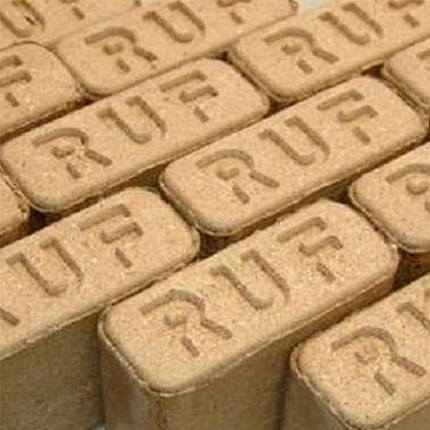

Wooden pellets

Wood pellets are an environmentally friendly type of fuel. During production, the use of foreign materials such as glue and plastics is not allowed, which significantly increases the service life of heating equipment.

Production Features

Natural fuel is a smart and efficient alternative to valuable minerals. Wood pellets allow for significantly reducing heating costs without losing heating efficiency. This is especially important as the cost of gas, coal, and fuel oil continues to rise. Wood pellets are produced from wood without the use of foreign materials such as glue and plastic. This type of pellet is suitable for various solid fuel boilers and is the ideal fuel for heating premises of various purposes, such as industrial premises, warehouses, residential houses, restaurants, and hotels, etc.

Fuel Characteristics

| Product Name | Efficiency | Ash Content |

|---|---|---|

| Wooden pellets EN plus A1 | 2.5 times more efficient than gas | Ash content up to 0.5%. Diameter - 6mm |

| Wooden pellets A1 | 2.41 times more efficient than gas | Ash content 0.7%. Diameter - 6 and 8 mm. |

| Wooden pellets A2 | 2.1 times more efficient than gas | Ash content 1.5%. Diameter - 6 and 8 mm. |

| Industrial pellets | 1.9 times more efficient than gas | Ash content 3.8%. Diameter - 8 mm. |

The size of wood pellets directly depends on the features of the equipment on which they are produced:

- Diameter: 6-10mm;

- Length: 10-50 mm;

With specific equipment, it is possible to produce pellets up to 2.5cm in length;

Advantages of Wood Pellets

This type of fuel has gained recognition in the market due to such positive features:

- High calorific value - up to 5 kilowatts per kilogram of fuel;

- Low moisture content - usually not more than 10%;

- Minimal pollutants emitted into the air during combustion;

- Low ash content.

Burning 1 ton of this natural fuel provides the same amount of energy as using 1.5 tons of conventional firewood or almost 500 cubic meters of gas.

We recommend you to buy this type of fuel to help you heat your premises during the cold season.

MANUFACTURING

PRODUCT SPECIFICATIONS

- Environmental friendliness and renewability

- High combustion efficiency

- Easy and convenient storage and usage

- Economical affordability

- Multifunctionality

- High ash content and emissions negatively affecting the environment

- Low combustion efficiency and heat loss

- Non-renewability of fuel

- Difficulty in transportation and storage

- More frequent need to replenish fuel supplies